3D-Printing

3D-Printing

What is 3D printing?

3D printing is an additive process in which the material is applied layer by layer. At InnovationSpace, we use FDM 3D printers (fused deposition modeling). The material (filament) is melted and applied to a print bed through an automatically moving nozzle, where it cools quickly. The next layer is then welded onto the previous one. As this process runs from bottom to top, support structures are required for overhangs. Some printers also allow the use of multiple nozzles, which enables printing with different materials.

Device traffic light: Yellow

You may only use our 3D printers after a safety briefing, either in person or via an introductory video and Moodle test (opens in a new window).

In the Innovation Space, we use a device traffic light (opens in a new window) system for the safety classification of devices. The colors green, yellow and red correspond to different safety instructions that must be observed before use.

Instruction

Safety instructions

Device traffic light category: Yellow

You may use these devices only after a safety briefing, either in person or via introductory video and Moodle test (opens in a new window). Please contact our lab manager Niklas Müller and make an appointment to use the 3D printer. Also familiarize yourself with our device traffic light. If you have any further questions, please do not hesitate to contact our responsible persons.

3D-Printing process

For 3D printing, a model of the object must first be created and imported into the corresponding software for the 3D printers (e.g. Fusion360 -> MakerBot Desktop/Ultimaker Cura). Settings such as support structures, printing speed and other parameters are then adjusted depending on the material and structure.

Advantages:

- Cheap production (for small quantities)

- Fast prototyping

- Freedom of form

- Quick and easy training

Examples

Devices

Makerbot Replicator 2

Makerbot Replicator 2 (Slicer: Makerbot Print)

The Makerbot has the device traffic light category: Yellow

The Makerbot has a slightly smaller build space than the Prusa and a finer nozzle.

As it does not have a heated print bed, large models cannot adhere to the build plate. It is therefore ideal for small 3D models.

The "Makerbot Print" software is easy to use, but does not offer as many setting options.

All further information about this 3D printer can be found on Moodle. (opens in a new window)

General Informationen

| Filament diameter: | 1.75 mm |

| Printing plate: | Acrylic with adhesive film |

| Temperature of the printing plate: | Not heated |

| Used material: | PLA |

| Software: | Makerbot Desktop |

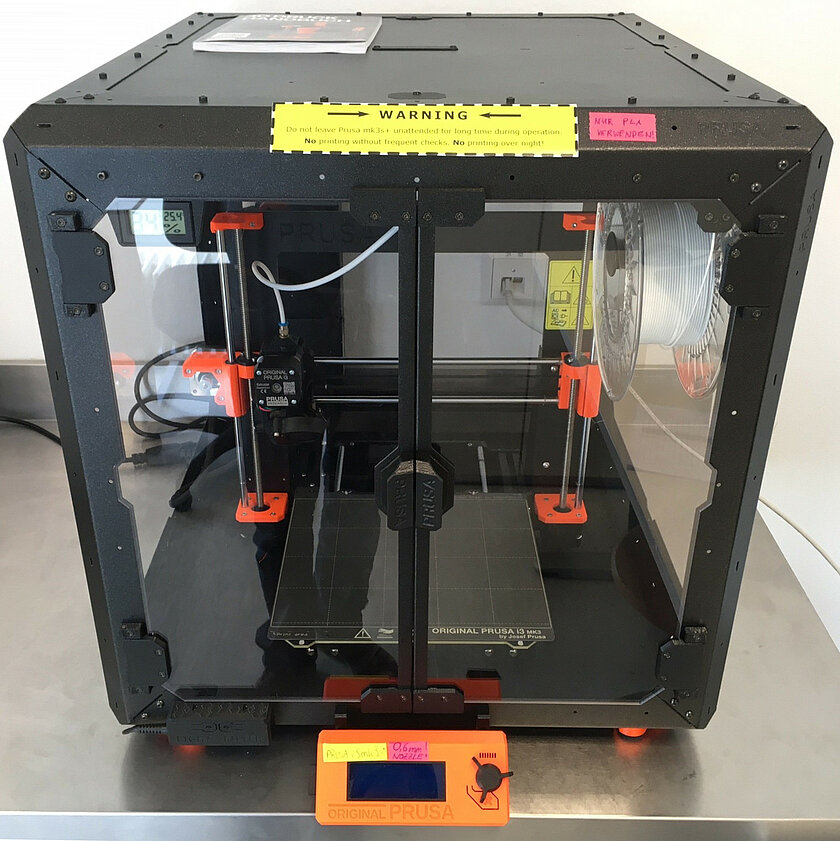

Prusa i3 mk3s+

Prusa mk3s+ (Slicer: Prusaslicer)

The Prusa mk3s+ has the device traffic light category: Yellow

The Prusa is a beginner-friendly all-rounder.

The "Prusaslicer" software offers extensive setting options and the function to repair defective 3D files.

All further information about this 3D printer can be found on Moodle. (opens in a new window)

General Informationen

| Filament diameter: | 1.75 mm |

| Printing plate: | PEI flexplate with smooth coated surface |

| Nozzle diameter: | 0,6mm |

| Materials used: | PLA and other bio-based plastics |

| Software: | Prusaslicer |

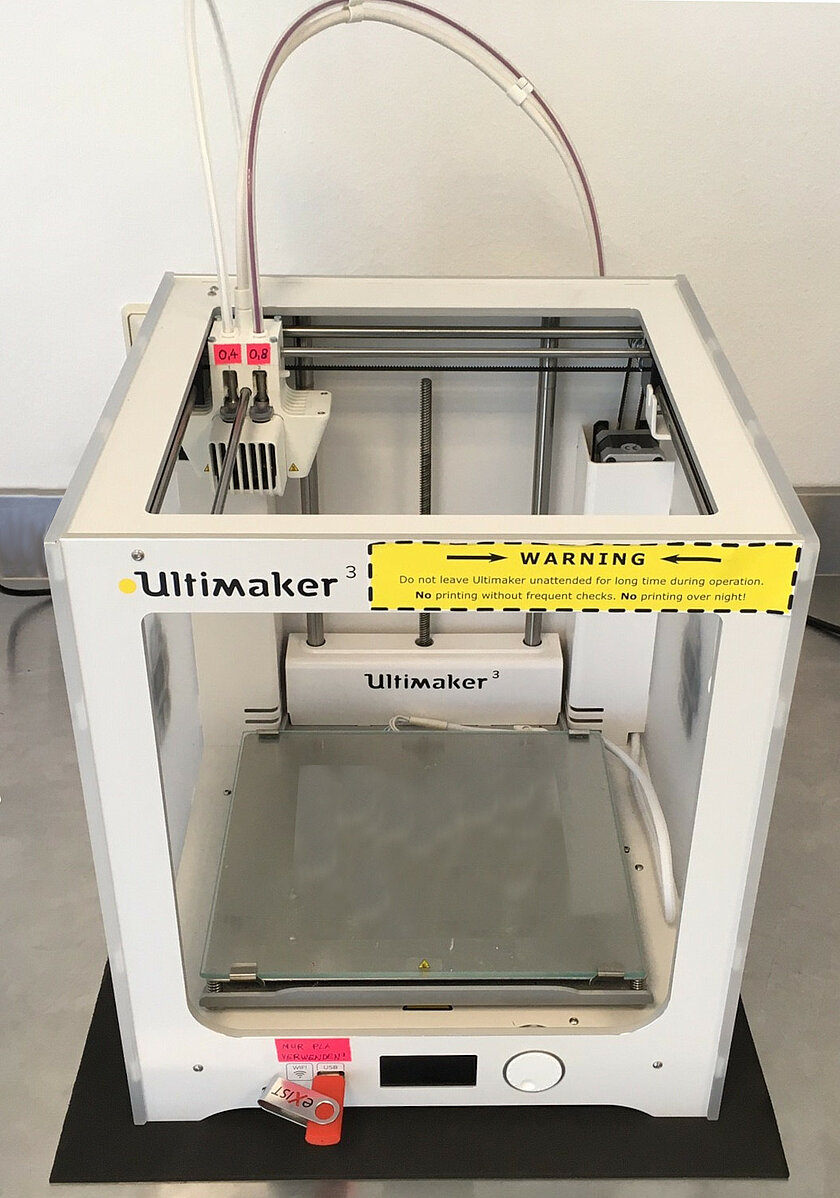

Ultimaker 3

Ultimaker 3 (Slicer: Ultimaker Cura)

The Ultimaker has the device traffic light category: Yellow

The Ultimaker has two extruder nozzles. This means that 3D models can be produced from two different materials / colors, but this is only recommended for advanced users.

The "Ultimaker Cura" software offers many setting options.

All further information about this 3D printer can be found on Moodle. (opens in a new window)

General Informationen

| Filament diameter: | 2.85 mm |

| Printing plate: | Heated glass printing plate |

| Temperature of the printing plate: | 20 - 100°C |

| Warm-up time of the printing plate: | 4 Min (20 -> 60°C) |

| Used materials: | PLA, PVA |

| Software: | Ultimaker Cura |

Videos

Top quality 3D scanning and printing

Print faster

3D-Printing Problems: Solutions Tips

3D printing filaments: properties + application examples