Equipment

Here you will find an overview of the equipment and machines available in the Innovation Space. These can only be used after a safety briefing. If you have any questions or concerns regarding the workshop, please contact the Innovation Space laboratory technology department.

Hand tools (mechanical)

Two workbenches with vices and non-slip mats are available in the prototyping workshop so that workpieces can be worked on safely. A selection of hand tools for wood and metal can be used for this purpose.

3D-Scanner

Three-dimensional objects can be captured and digitized using a 3D scanner. This is particularly recommended for organic, complex shapes, as it is much faster than manual modeling on the computer.

Foil plotter

With a cutting plotter, a material is cut automatically using a fine cutter blade. In addition to classic adhesive film, the existing machine can also be used to cut film for ironing onto textiles, for example.

Mixed Reality (AR/VR)

In MR, special hardware and software, such as MR glasses, are used to create an artificial reality or supplement the perception of the real environment. In virtual reality (VR), the user is completely immersed in a virtual world. In augmented reality (AR), the user sees the real world and is shown additional information.

Electrotechnology

Building prototypes sometimes also involves electronics. The prototyping workshop contains a small selection of hand tools and measuring equipment as well as a set for programming electronic chips (microcontrollers).

Hand tools (electric)

For the mechanical production of prototypes made of wood and metal, the prototyping workshop provides a large selection of electric hand machines.

Electric machines

Stationary equipment, such as a pillar drill and disk sander, are also available in the workshop.

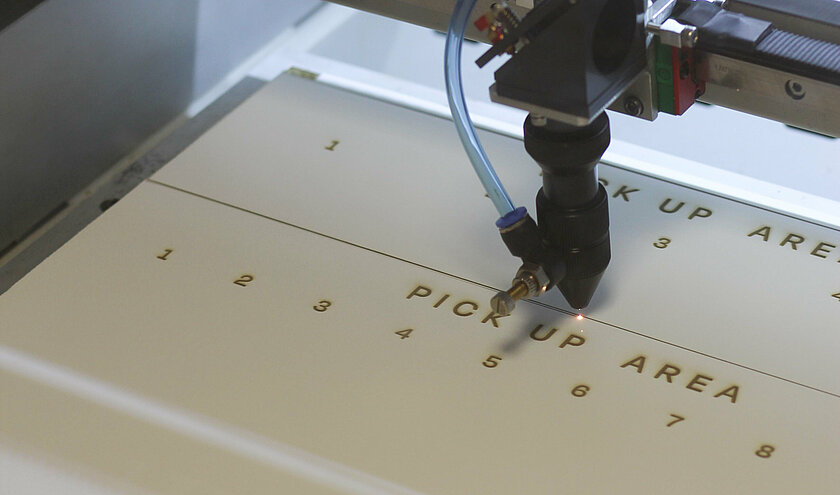

CNC milling

CNC milling is a high-precision machining process based on computerised numerical control, i.e. computer-assisted machine control. The CNC milling process is carried out by a microcomputer which is integrated in the control unit of the machine tool. The efficient process is excellently suited for the production of parts in both small and large quantities.

Screen printing

As the name suggests, in this process ink is applied to the workpiece through a stencil applied to a fine-mesh screen. As fine details are also reproduced on the screens, this printing technique is very precise. The production of a stencil involves a certain amount of work, which is why screen printing is particularly suitable for medium to large quantities.

Sewing & embroidery machine

The prototyping workshop is equipped with a high-quality electric sewing machine for processing textiles. This is complemented by the CNC embroidery machine, which can be used to automatically produce embellishments and lettering.