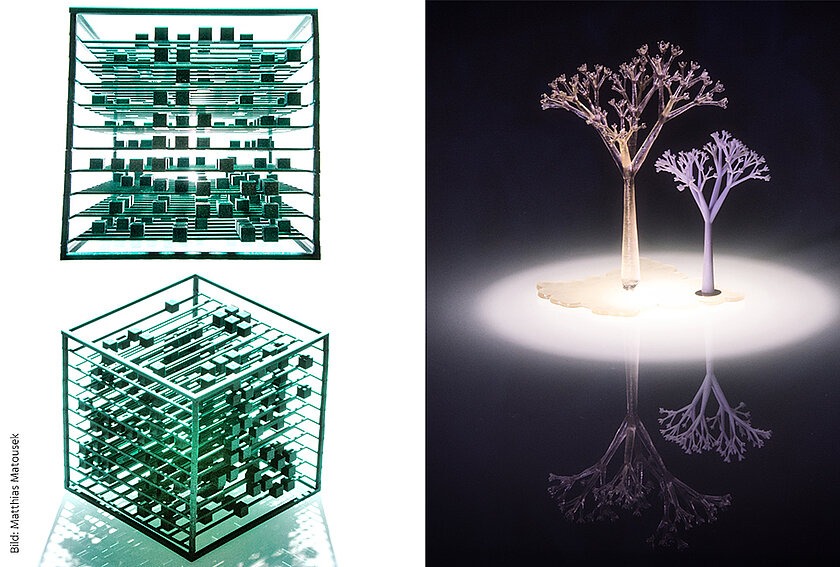

An algorithm that transforms personal memories such as texts, photos or pieces of music into art objects from the 3D printer: With this, Gerhard Habiger and Matthias Matousek from the "BitArt" team from Ulm took first place in the 1st South German 3D Printing Challenge. The jury found: This innovative idea has real potential.

The winning team was surprised: "By taking part in the competition, we wanted to first test whether our idea would be accepted," says Matthias Matousek. "Winning now gives us the push to actually implement our business idea".

Second place went to Leonie Fensterle from Stuttgart with her personalised eyebrow stamp "Kashello". Her idea: With the help of a scan app, customers* receive a stamp perfectly matched to their face with a worked-out hair structure for eyebrow styling, which saves valuable time in front of the mirror. The jury was particularly impressed by the business plan of the runners-up and the potential of the idea for patients* with loss of facial hair.

In third place was a surgical forceps from the 3D printer. Julian Kufner from Staig wants to enable hospitals to print disposable medical products directly on site from recyclable material with "pliers_one" in order to save long delivery routes. The jury particularly liked the idea that hospitals (for example in crisis areas) could thus supply themselves with surgical tools.

The jury also awarded three special prizes: A young talent prize for the youngest team, a special prize for an idea with a special social impact and one for the most beautiful product design.

Goal of the challenge: Bringing ideas out of heads and into reality

The idea for the 3D printing challenge was developed within the framework of the InnoSÜD sub-project "Physical, Augmented & Virtual Reality Logistics Living Lab" at the Neu-Ulm University of Applied Sciences. In this project, Prof. Dr.-Ing. Oliver Kunze, Dr. Fang Li and Fabian Frommer are looking at how 3D printing technologies can be used in logistics, for example, to shorten delivery routes. In accordance with the "Open Lab" principle, students, but also regional companies, can test their own 3D printing ideas in the lab.

"The 3D printing challenge complements the transfer of knowledge that we pursue in InnoSÜD," explains Professor Kunze. "Just like in our Open Lab, the Challenge is about taking ideas out of our heads and turning them into reality, and promoting ideas for new business models".

To ensure that the implementation into reality really succeeds, the competition was structured in two stages, explains Fabian Frommer, who as a research assistant in the project co-organised the competition: "First, the participants had to design a product and print it out as a prototype. The teams with the best ideas were then asked to draw up a business plan that highlighted aspects such as costs, profit or marketing channels".

The product idea and business plan were presented by the winners* of the preliminary rounds at the final on 20 October 2020. Although the event had to take place virtually, it was still an inspiring and exciting event for finalists and prize donors.

After the great response, the organisers want to continue the competition: Next year, the 3D printing challenge is set to grow and inspire even more tinkerers from all over Germany - and beyond.

Prizes and know-how: companies from the region and a YouTuber supported the competition

There were attractive prizes to be won in all aspects of 3D printing and the start of a business: from shopping vouchers for 3D printing material to workshops on various 3D printing techniques, as well as on founding and marketing, right through to the opportunity to introduce yourself to a specialist audience at the Augsburg trade fair. The finalists* also qualified for an internship at Daimler Evobus - and for relaxation, the first-placed participants received VIP tickets for the ratiopharm arena.

In addition, the winning team was allowed to present their product in a joint video with YouTuber Andreas Weiss. As "3D Printing Andi", his videos on YouTube introduce 3D printing techniques to a good 35,000 subscribers* and thus reach several hundred thousand viewers* per video.

The trophies in gold, silver and bronze for places 1 - 3 were created by designer Gesa Pickbrenner especially for the competition and made by Hilscher - naturally using 3D metal printing techniques.

Cups and prizes were donated by companies from the region, who also contributed their expertise to the jury and gave the participants* practical tips. "Without the generous support of our prize donors, we would not have been able to carry out the 3D printing challenge on this scale," Professor Kunze thanked.

The prize donors were present:

Volksbank Ulm-Biberach e.G.

Max Hilscher GmbH

Honold Logistics Group

Fabb-It pro3D GmbH

EvoBus GmbH

EOS GmbH

Mark3D GmbH

Filament W